Our Machines

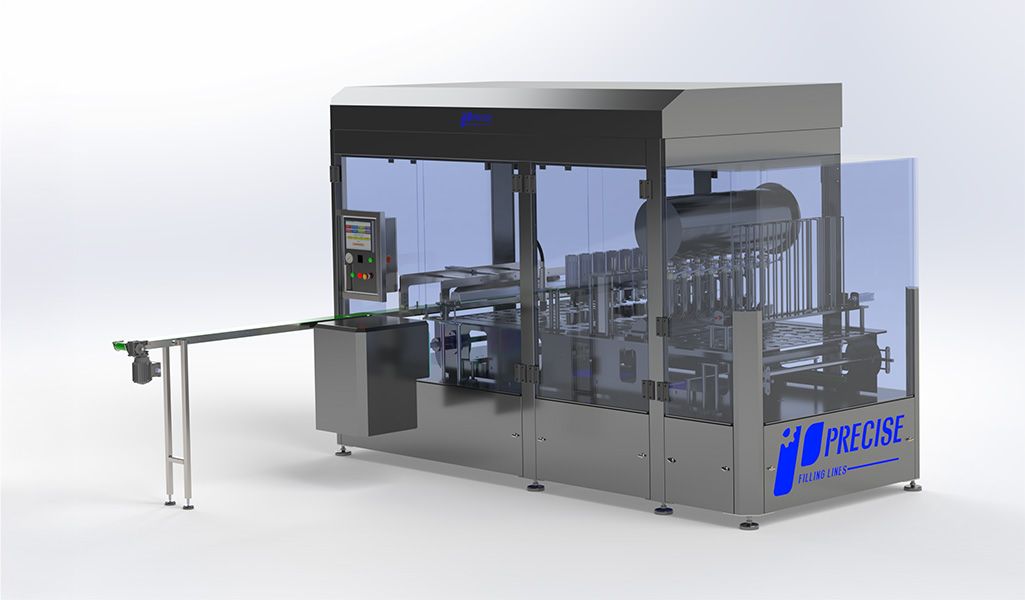

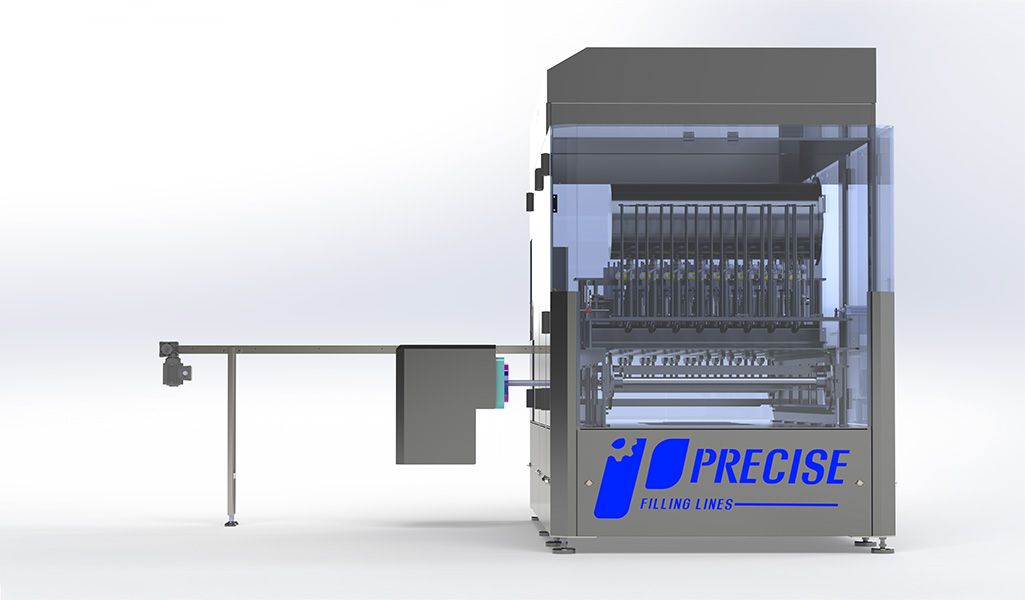

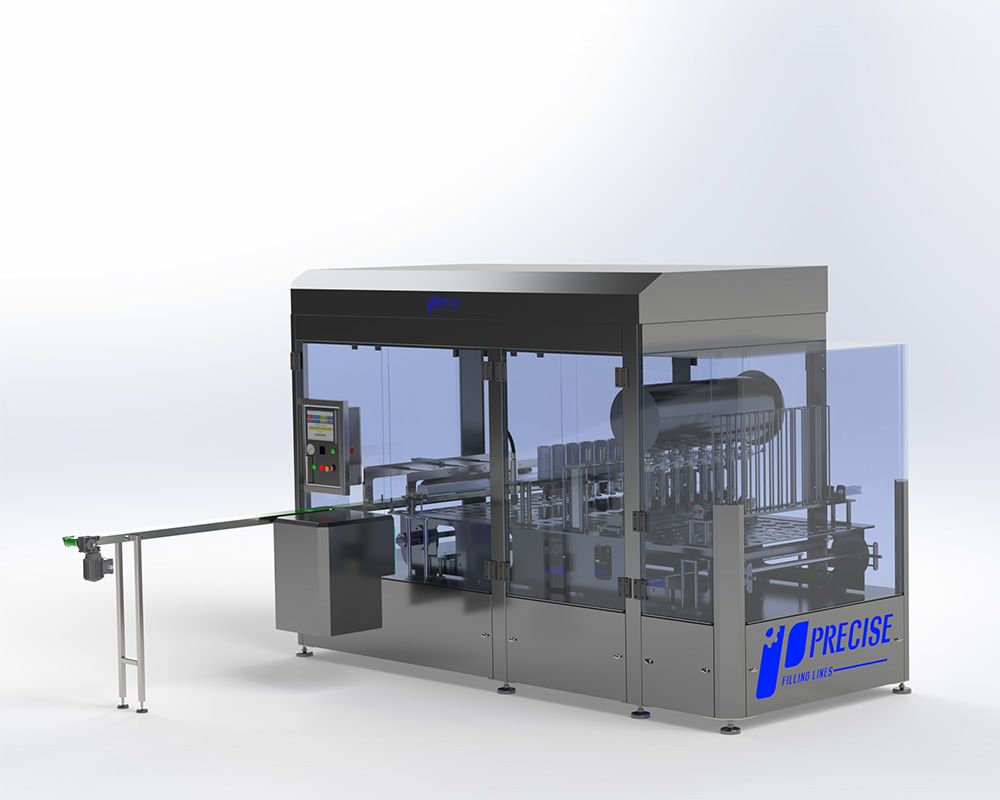

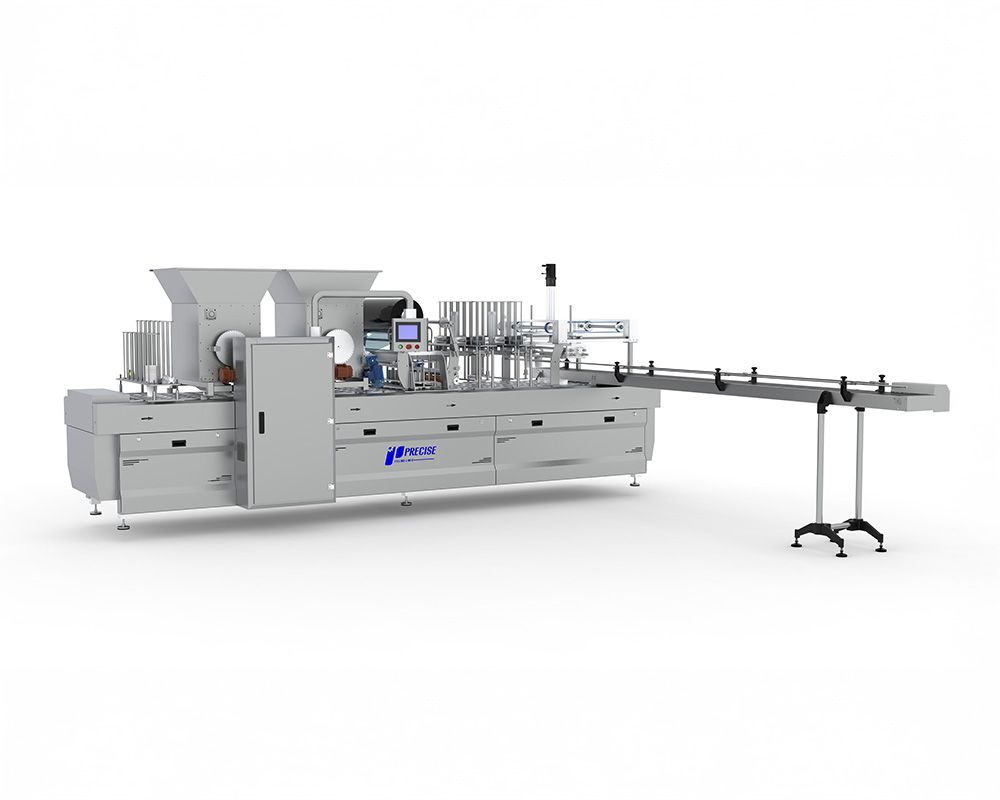

Rotary Filling and Capping Machine Lines

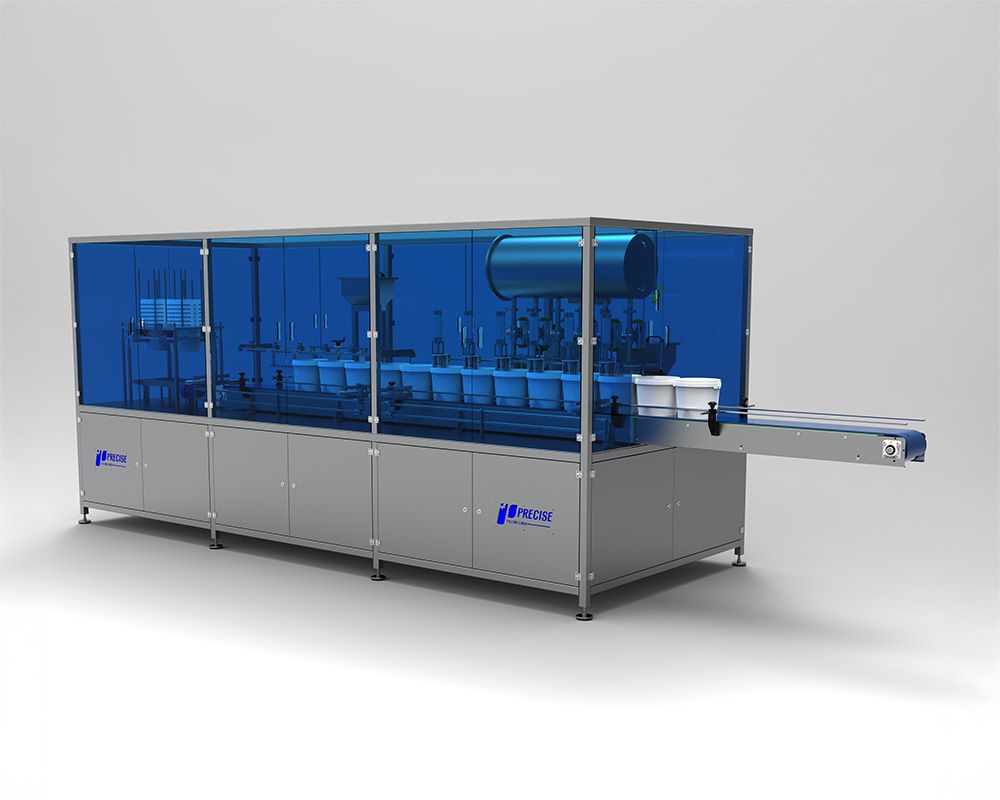

The movement of the machine is driven by a motor and gearbox, which rotates the rotary table. The cup drops automatically from the slide plate. The filling process is controlled by a photocell system; it automatically fills to the desired weight upon detecting the cup. The pre-cut aluminum lid is automatically placed onto the cup, and the lids are sealed under the sealing head. Date coding is performed under the date setting unit. Finally, finished products are transferred to the conveyor belt with the help of a lifting arm.

Technical Specifications

| MODEL | PRC | ||||

|---|---|---|---|---|---|

| Capacity | 1500 per hour

piece |

||||

| Diameter | Between 40mm and 160mm | ||||

| Weight | Between 10g and 1000g | ||||

| Machine Voltage | 380W – (1 – 1.5 kW consumption) | ||||

| Material | 304 grade stainless | ||||

| Air Pressure | Minimum 6 bars – Maximum 8 bars | ||||

| Warranty | 2 Years | ||||

Working Principle

The machine operates in a very simple manner. The process generally consists of the following steps:

Preparation: The machine prepares the materials and equipment necessary to perform the filling and capping operations. These include components such as filling nozzles, capping heads, product hopper, and control panel.

Product Filling: In the first step, filling nozzles transfer the liquid or powder product from the product hopper to the target packaging at the specified dosage. This filling process is controlled by precise metering systems to ensure the correct amount of product is delivered.

Sealing Process: After the filling process, the sealing caps engage to close the packaging. These caps seal the packaging using various sealing methods. For example, screw caps, stoppers, or cap sealing systems can be used.

Control and Adjustments: The machine continuously performs checks and adjustments to ensure that the filling and capping processes are carried out correctly. This includes properly adjusting the product quantity, capping tightness, filling speed, and other parameters.